Our world-leading technology encompasses solutions

for the characterization of particles, powders, and porous materials.

Surface Area

Surface area by gas adsorption including BET surface area

Porosity

Pore size, volume, and distribution by gas adsorption and mercury porosimetry

Density

Absolute density of solids, powders, and slurries by gas pycnometry. Automated envelope density of irregular solids and compressed bulk density (T.A.P).

Powder Flow

Shear and dynamic measurements of powder rheology and particle interactions

Activity

Catalyst activity including chemisorption, temperature-programmed reactions, and lab-scale reactor systems

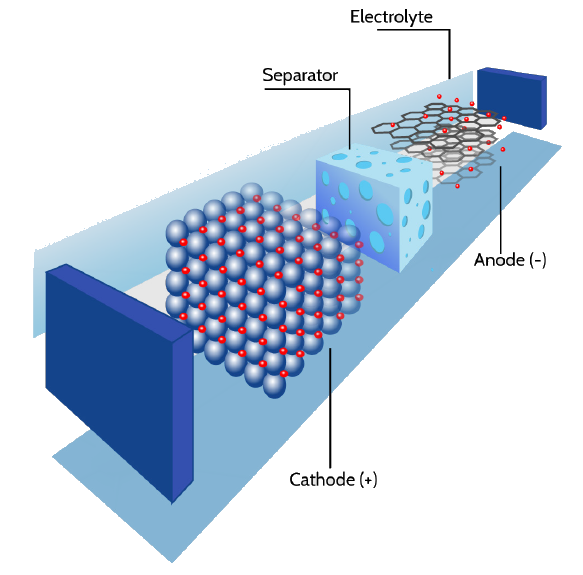

Li-ion Battery Components

Lithium-ion (Li-ion) batteries are an advanced battery technology which have four major components: anode, cathode, separator, and electrolyte.

At Micromeritics we have instrumentation for all stages of battery production starting from the raw material precursors to the final battery cell.

In the future the liquid electrolyte may be replaced by a solid electrolyte for improved safety and performance.

Instruments for every component of your battery

Select category below to see relevant method & instruments

Precursor Materials

Surface Area

- Increase capacity

- Facilitates fast charging

- Improve charge/discharge performance

![]()

Particle Size

- Maximize capacity

- Critical for high energy density

- Influence coulomb efficiency

Density

- Optimize electrode packing density

- Maximize mass/volume density

- Minimize irreversible capacity

Anode/Cathode

Surface Area

- Increase capacity

- Facilitates fast charging

- Improve charge/discharge performance

- Tailor binder needed for adhesion

Density

- Optimize electrode packing density

- Maximize mass/volume density

- Minimize irreversible capacity

Powder Flow

- Control slurry agglomerates and dispersibility

- Optimize electrode packing density

- Improve battery efficiency

- Longer battery life

Separator

Porosity

- Critical to safety and reliability

- Improve energy/power density

- Optimize capacity

- Longer cycle life

Density

- Critical to safety and reliability

- Consistent ceramic material

- Longer battery life

Instruments for every step in the Li-ion battery manufacturing process.

Our instruments are there every step of the way from precursor consistency to the electrode slurry preparation, coating, drying, and calendaring, and final cell electrolyte filling.

Li-ion Battery Instrumentation

Micromeritics best-in-class material characterization instrumentation in our core areas of expertise.

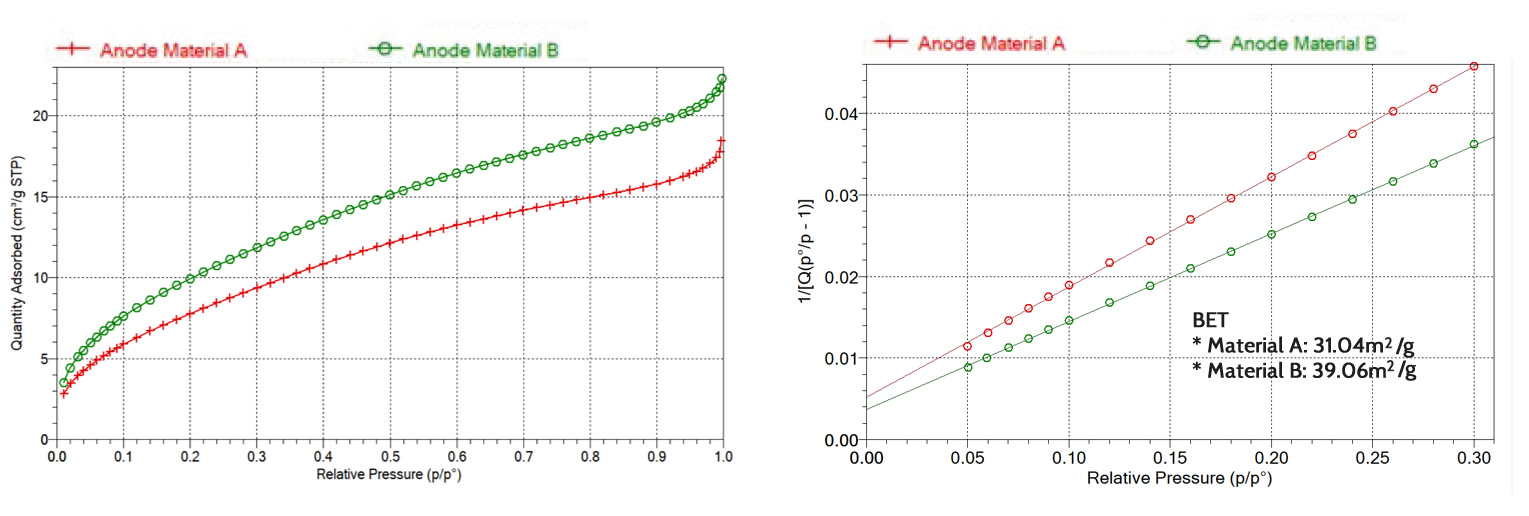

Surface Area Measurement

Results Example

Results Example

Adsorption Isotherm and BET Surface Area Plot of Next Generation Anode

Value for Battery Industry

- Understanding the porosity of the electrode materials is important to guarantee the right ion accessibility and charging speed.

- BET surface area, pore volume and pore size distribution help to optimize your battery components.

Instrument Details

Instrument Details

Our extensive range of gas adsorption analyzers offer convenient solutions to realize your R&D, quality control, and manufacturing needs.

- Pore size can be measured from 0.3nm to 300nm using a variety of different models

- Water vapor adsorption studies allow the investigation of a material’s sensitivity towards water

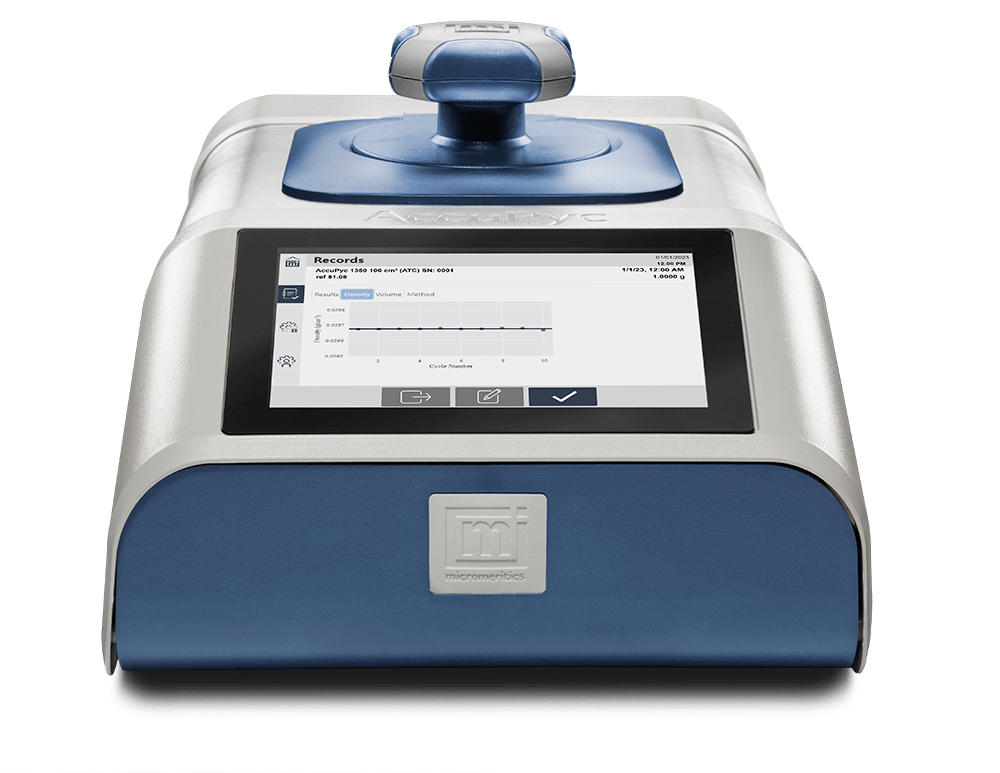

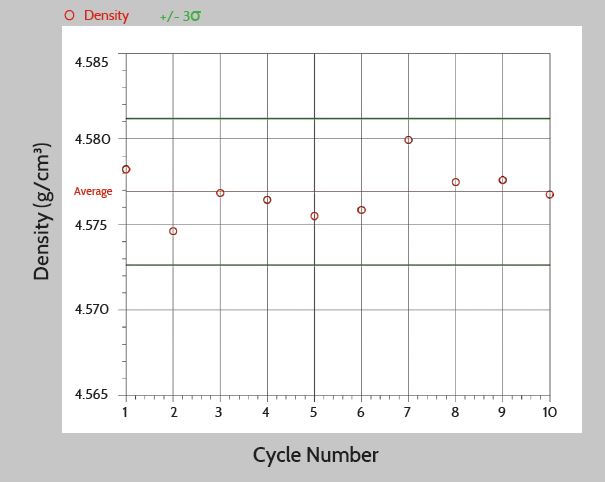

Density Measurement

Results Example

Results Example

Density of NCM Ternary Cathode Material

Data Summary

- Average: 4.5769 g/cm3

- Standard Deviation: 0.0014 g/cm3

Value for Battery Industry

- High T.A.P. density of precursors is expected to obtain a high volumetric energy density.

- The true density is a good indicator of purity and composition of the cathode which can be used to improve the overall performance of the battery.

- Monitoring true density of the electrode material ensures stability of the slurry coating and drying process

Instrument Details

Instrument Details

The AccuPyc uses Gas Pycnometry and the GeoPyc uses a unique displacement technique to determine the:

- True, absolute, and skeletal density

- Apparent volume and density

- Envelope volume and density

- Bulk volume and density

Combining data from these two techniques enables the determination of the percent porosity and total pore volume

![]()

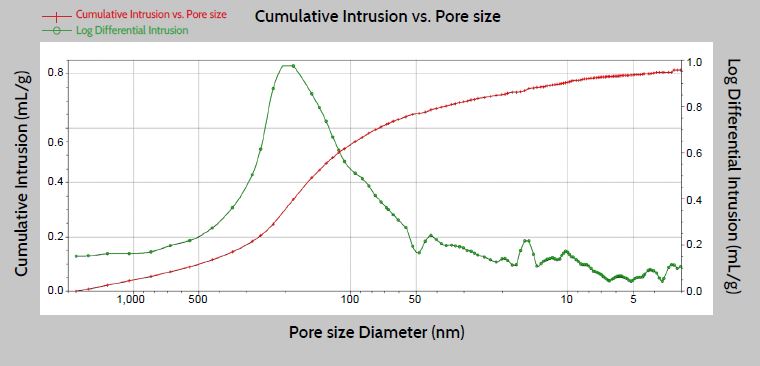

Porosity

Results Example

Results Example

Separator Pore Size Distribution from the AutoPore

Intrusion Data Summary

- Total intrusion volume: 0.813 mL/g

- Median pore diameter: 155 nm

- Porosity: 53.1%

Value for Battery Industry

- Understanding the porosity of the electrode materials is important to guarantee the right ion accessibility and charging speed.

- BET surface area, pore volume and pore size distribution help to optimize your battery components.

Instrument Details

Instrument Details

Mercury porosimetry is a uniquely valuable technique which delivers speed, accuracy and the comprehensive characterization of many sample properties:

- pore size, 3nm to 500 µm

- total pore volume

- total pore surface area

- percent porosity

- sample densities (bulk and skeletal)

- particle size

Our extensive range of gas adsorption analyzers offer convenient solutions to realize your R&D, quality control, and manufacturing needs.

- Pore size can be measured from 0.3nm to 300nm using a variety of different models

- Water vapor adsorption studies allow the investigation of a material’s sensitivity towards water

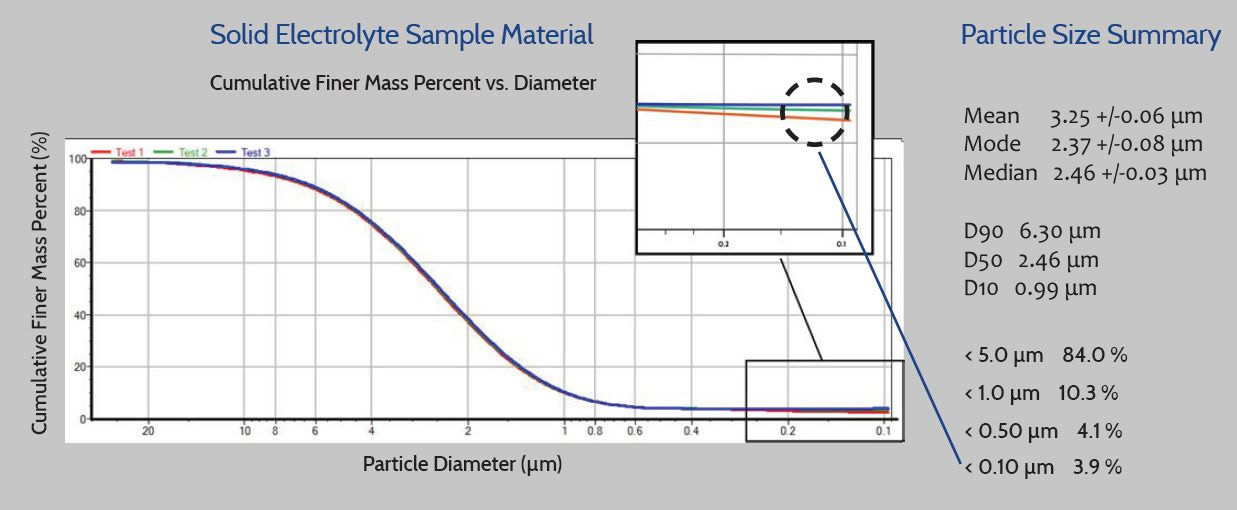

Particle Size

Results Example

Results Example

Value for Battery Industry

- The SediGraph is the only instrument that can precisely report weight percent of particles <0.1μm.

- Industry leader for rough electrode and other precursor materials.

- Optimize particle size ratio of cathode and solid electrolyte to maximize the energy density.

Instrument Details

Instrument Details

The SediGraph remains the global standard for particle size analysis by sedimentation after five decades, whether in a rugged production environment or a controlled laboratory setting.

- Sedimentation uses well understood physical laws and easy to measure properties that do not require trial and error modeling

- Provides complete sample mass accountability and quantifies the fine content outside the measurement range

- Uses higher material concentration than many other techniques ensuring a representative sample

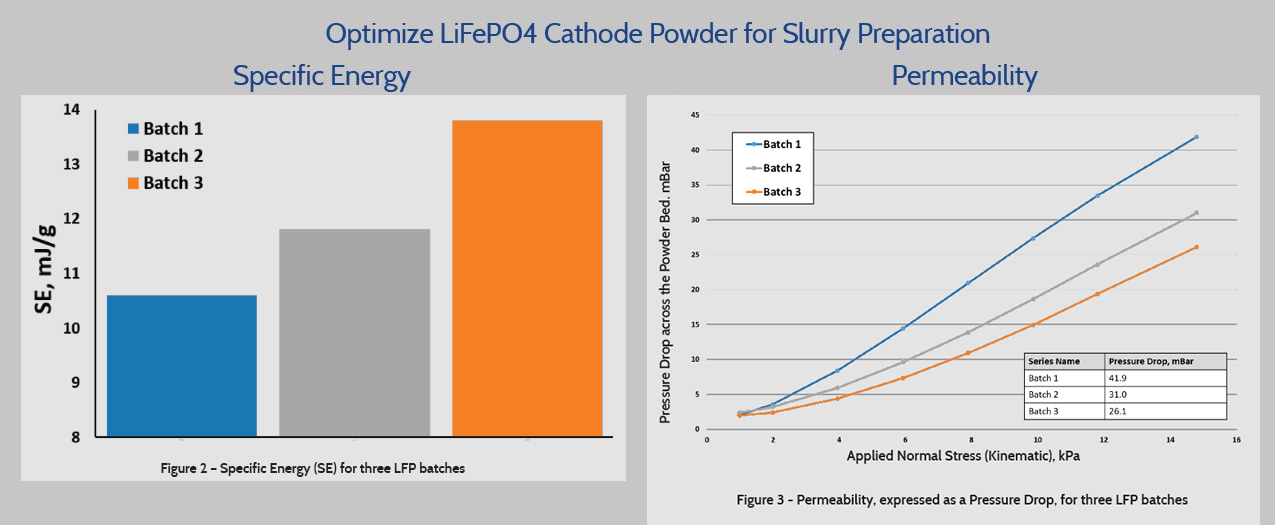

Powder Flow

Results Example

Results Example

Value for Battery Industry

- Understanding a powder’s Specific Energy, an indicator of inter-particular friction and mechanical interlocking, can help reduce agglomerates in the electrode slurry.

- Determining and optimizing Permeability, a measure of a powder’s ability to release air, can improve slurry dispersion and cavity filling in wet or dry systems.

Instrument Details

Instrument Details

The FT4 provides comprehensive flow property characterization of a powder and is now established as a universal powder tester. Optimize manufacturing processes by quantifying a powder’s.

- Resistance to flow in motion

- Shear strength

- Shear against the wall

- Bulk density

- Compressibility

- Permeability

Relevant Resources

Application notes

- Characterizing Advanced Battery Anodes With Gas Adsorption BET Surface Area and DFT Surface Energy

- Characterizing Li-ion Battery Separators

- Optimizing Li-ion Battery Electrode Manufacturing – Yield Case Study

- Confirmation of Pore Formation Mechanisms in Biochars and Activated Carbons by Dual Isotherm Analysis

- Particle Size Determination of Porous Powders Using the SediGraph

- Characterization of carbon using the micromeritics 3Flex

- Assessing Batch to Batch Variability of Bulk Chemicals

- Quantifying Caking using the FT4 Powder Rheometer

- Developing a Design Space for a Die Filling Operation

- The Influence of Particle Size and Shape on Flow Properties

- Fluidisation/Processability of Powder Coatings & Batch Variability in Spray Coating

Videos

- Analytical Methods to Ensure Battery Raw Material and Electrode Performance

- Physical Characterization Methods for Cathode Powders

- Lithium-ion Battery Separator: Pore Structure Determination Using Mercury Intrusion Porosimetry

- Optimizing Yield for Li-ion Battery Electrode Manufacturing for both Wet and Dry Processes

- Characterizing Advanced Battery Anodes with Gas Adsorption BET Surface Area and DFT Surface Energy

- Best Practices for BET Surface Area

- Exploiting Multiple Gas Adsorption Isotherms for Consistent Pore Size Analysis

- Understanding Density Measurement Techniques

- Measuring and Quantification of Caking in Powders

- Physisorption and Chemisorption – Sample Preparation and the Impact on Results

- Unified Approach to Understanding Porous Materials

- Understanding Surface Area Measurements

- Techniques Applicable to the Study of Porous Materials

How Can We Help?

Advancing the future of Li-ion batteries one measurement at a time.

Despite their overall advantages, Li-ion batteries have their drawbacks, and many areas are being investigated that will be commercialized in the coming decade. We are here to provide sustainable solutions to speed your battery development with quality data, customer service, our particle testing lab, and virtual or onsite product demonstrations.