Our world-leading technology encompasses solutions

for the characterization of particles, powders, and porous materials.

Surface Area

Surface area by gas adsorption including BET surface area

Porosity

Pore size, volume, and distribution by gas adsorption and mercury porosimetry

Density

Absolute density of solids, powders, and slurries by gas pycnometry. Automated envelope density of irregular solids and compressed bulk density (T.A.P).

Powder Flow

Shear and dynamic measurements of powder rheology and particle interactions

Activity

Catalyst activity including chemisorption, temperature-programmed reactions, and lab-scale reactor systems

OUR SOLUTIONS

Micromeritics offers the most comprehensive portfolio of high-performance instruments

to characterize the materials required to achieve a more sustainable future

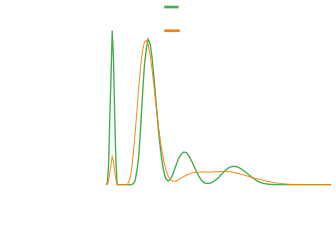

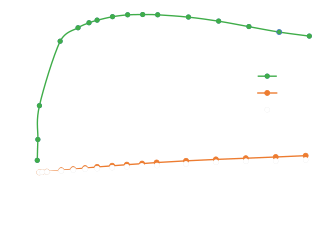

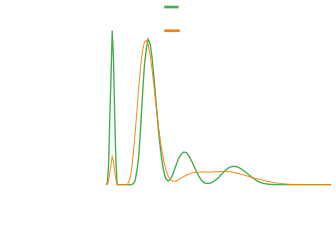

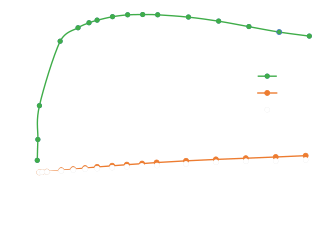

INTERACTIONS OF H2 ON SUPPORTED Ni CATALYST

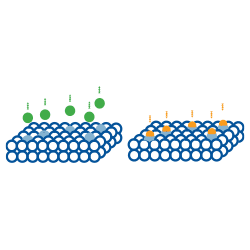

3Flex CHEMISORPTION

Offers physisorption and static/dynamic chemisorption for characterizing catalysts and their supports

- Understand multi-metal catalysts’ effects on activation and adsorption of active species

- Select catalysts providing a higher turnover frequency

- Investigate influence of heat of adsorption

AutoChem III

Utilizes dynamic techniques to characterize the materials active sites

- Optimize adsorption and dissociation of H2/O2 on electrolysis electrodes

- Understand if desorption occurs near reaction conditions

- Measure and quantify acid or base sites to optimize reactivity and selectivity

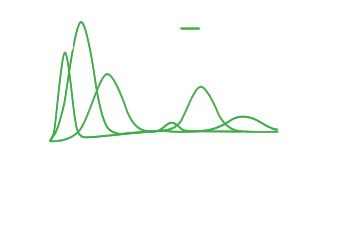

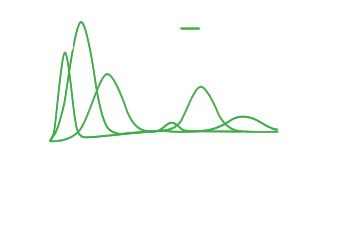

DECONVOLUTION CO2 DESORBED BY CaO/MgO

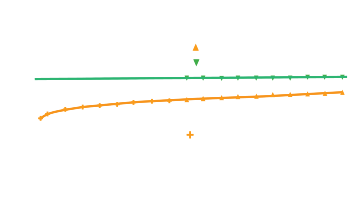

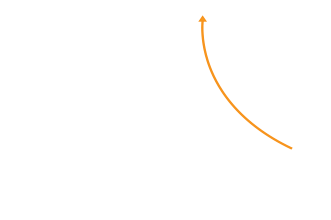

PRESSURE IMPACT ON REDUCTION TEMPERATURE

Cu-OXIDE CATALYST

ICCS

Provides in-situ characterization to understand the effect of reaction conditions on the catalyst

- Understand changes in performance over extended periods

- Determine deactivation mechanism to maximize the catalysts’ lifetime

- Monitor changes in active sites, oxidative state, metal dispersion, and desorption behavior

FR/MR REACTOR SYSTEMS

Benchtop reactor studies to understand and optimize catalyst performance

- Understand reaction kinetics to optimize operating parameters and conversion

- Measure selectivity, efficiency, and lifetime of catalysts

- Study of reactions requiring a liquid/gas separator at pressure and temperature

REDUCTION OF CO2 IN THE SABATIER REACTION

COMPLETE PORE SIZE DISTRIBUTION (PSD)

USING DUAL NLDFT FOR ACTIVATED CARBON

3Flex

High-performance adsorption analyzer for measuring surface area, pore size and volume

- Understand adsorbent regeneration cost and best operating parameters

- Optimize pore size to maximize uptake capacity of the adsorbent

- Predict the selectivity of a gas mixture using Ideal Adsorption Solution Theory (IAST)

BreakThrough Analyzer

Precise characterization of adsorbent or membrane under process relevant conditions

- Lifetime and cycling studies to choose best adsorbent technology

- Measure kinetic performance of adsorbents

- Understand humidity effects for CO2/N2 competitive adsorption

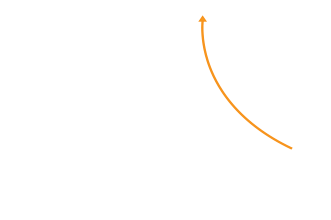

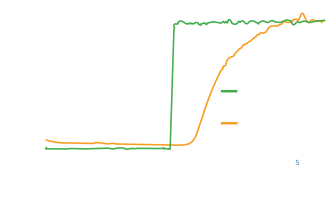

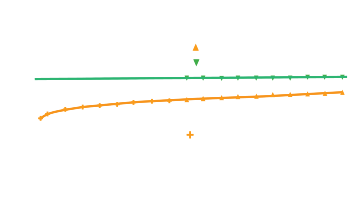

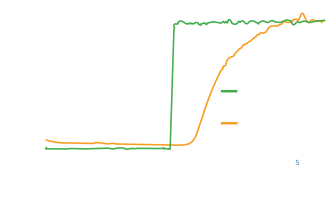

C02 BREAKTHROUGH CURVES SiAl LOADED WITH PEI

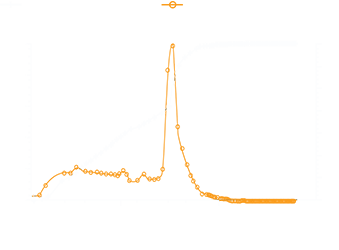

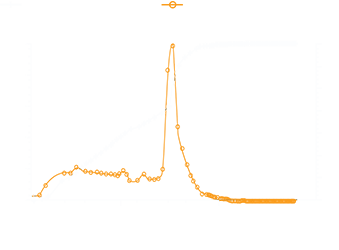

NaY ZEOLITE CUMULATIVE INTRUSION VS PORE SIZE

AutoPore

Mercury porosimetry analysis permits detailed porous material characterization

- Characterize pore size to understand diffusion into adsorption sights

- Study and optimize pore size distribution, total pore volume, percent porosity, particle size, and total surface area

- Assure reproducible adsorbent manufacturing process

HVPA

Static volumetric method to obtain high-pressure adsorption and desorption isotherms

- Investigate the quantity of H2 or CO2 adsorbed

- Increase productivity and reduce cost by optimizing the adsorption/ desorption cycle

- Study candidate materials and CO2 storage sites

H2 ADSORPTION ON MICROPOROUS CARBON

- CATALYSTS INSTRUMENTS

-

INTERACTIONS OF H2 ON SUPPORTED Ni CATALYST

View Instrument Details

View Instrument Details3Flex CHEMISORPTION

Offers physisorption and static/dynamic chemisorption for characterizing catalysts and their supports

- Understand multi-metal catalysts’ effects on activation and adsorption of active species

- Select catalysts providing a higher turnover frequency

- Investigate influence of heat of adsorption

View Instrument DetailsAutoChem III

Utilizes dynamic techniques to characterize the materials active sites

- Optimize adsorption and dissociation of H2/O2 on electrolysis electrodes

- Understand if desorption occurs near reaction conditions

- Measure and quantify acid or base sites to optimize reactivity and selectivity

DECONVOLUTION CO2 DESORBED BY CaO/MgO

PRESSURE IMPACT ON REDUCTION TEMPERATURE

Cu-OXIDE CATALYST

View Instrument Details

View Instrument DetailsICCS

Provides in-situ characterization to understand the effect of reaction conditions on the catalyst

- Understand changes in performance over extended periods

- Determine deactivation mechanism to maximize the catalysts’ lifetime

- Monitor changes in active sites, oxidative state, metal dispersion, and desorption behavior

View Instrument DetailsFR/MR REACTOR SYSTEMS

Benchtop reactor studies to understand and optimize catalyst performance

- Understand reaction kinetics to optimize operating parameters and conversion

- Measure selectivity, efficiency, and lifetime of catalysts

- Study of reactions requiring a liquid/gas separator at pressure and temperature

REDUCTION OF CO2 IN THE SABATIER REACTION

- ADSORBENTS AND MEMBRANES INSTRUMENTS

-

COMPLETE PORE SIZE DISTRIBUTION (PSD)

USING DUAL NLDFT FOR ACTIVATED CARBON

View Instrument Details

View Instrument Details3Flex

High-performance adsorption analyzer for measuring surface area, pore size and volume

- Understand adsorbent regeneration cost and best operating parameters

- Optimize pore size to maximize uptake capacity of the adsorbent

- Predict the selectivity of a gas mixture using Ideal Adsorption Solution Theory (IAST)

View Instrument DetailsBreakThrough Analyzer

Precise characterization of adsorbent or membrane under process relevant conditions

- Lifetime and cycling studies to choose best adsorbent technology

- Measure kinetic performance of adsorbents

- Understand humidity effects for CO2/N2 competitive adsorption

C02 BREAKTHROUGH CURVES SiAl LOADED WITH PEI

NaY ZEOLITE CUMULATIVE INTRUSION VS PORE SIZE

View Instrument Details

View Instrument DetailsAutoPore

Mercury porosimetry analysis permits detailed porous material characterization

- Characterize pore size to understand diffusion into adsorption sights

- Study and optimize pore size distribution, total pore volume, percent porosity, particle size, and total surface area

- Assure reproducible adsorbent manufacturing process

View Instrument DetailsHVPA

Static volumetric method to obtain high-pressure adsorption and desorption isotherms

- Investigate the quantity of H2 or CO2 adsorbed

- Increase productivity and reduce cost by optimizing the adsorption/ desorption cycle

- Study candidate materials and CO2 storage sites

H2 ADSORPTION ON MICROPOROUS CARBON

Carbon capture, utilization, and storage, CCUS, is an important portfolio of emissions reduction technologies.

A clean energy future includes electric vehicles, valorizing CO2 for synthetic fuels,

and industrial plants using carbon capture

CO2 CAPTURE

Adsorbents, Membranes

- Effect of water on performance

- Tailor pore size of membrane for application

- Optimize adsorption / desorption cycle to minimize cost

CO2 STORAGE

Adsorbents, Membranes

- Determine lifetime, cycling performance

and adsorbent CO2 capacity - Understand local pollutants’ effect on adorbent cycle life

CO2 UTILIZATION

Catalysts

- Evaluate effects of time-on-stream, temperature, and pressure on process economics

- Textural characterization of catalyst support

- Ascertain deactivation mechanisms

- Optimize metal dispersion and activity

- Determine reaction kinetics, activity, and selectivity of the catalyst

Applications

Industrial

Capture

Amine

Scrubber

Direct

Air Capture

Applications

Metal Organic Framework

Function-

alized Porous Material

Activated Carbon

Applications

Synthetic Fuels

Shipping

E-NH3, E-methanol

Aviation

E-kerosene

Relevant Resources

Adsorbents and Membranes

- Analysis of adsorbents for direct air capture of carbon dioxide using breakthrough analysis

- Using the ASAP 2020 for Determining the Hydrogen Adsorption Capacity of Powders and Porous Materials

- Micropore Analysis of Zeolites Using the ASAP 2420

- Adding a Custom Model to the NLDFT Library: A CO2 GCMC Model for Carbons

- Characterization of Carbons Using a Micromeritics 3Flex

- Adding a custom model to the NLDFT library – a CO2 GCMC model for carbons

- Carbon Dioxide Characterization of Carbons with the TriStar II 3020

- Diffusion of Nitrogen and Methane in Clinoptilolites Tailored for N2-CH4 Separation (ASAP 2010)

- The Heat of Adsorption of Hydrogen Gas on Lanthanum Pentanickel

- Multicomponent Breakthrough Adsorption Water/ethanol Competitive Adsorption On A Zeolite

Catalyst

- Paper: On the Application of an In Situ Catalyst Characterization System (ICCS) and a Mass Spectrometer Detector as Powerful Techniques for the Characterization of Catalysts

- Paper: Confirmation of Pore Formation Mechanisms in Biochars and Activated Carbons by Dual Isotherm Analysis

- Effect of O2 Traces in the Carrier Gas on Quantifying the Active Species in Catalysts

- Evaluating Catalyst Substrates with the GeoPyc

- Temperature-Programmed Reduction Using the AutoChem

- Characterization of Acid Sites Using Temperature-Programmed Desorption

- Characterization of Supported Palladium, Hydrogen Sorption – by Jason Exley

- Characterization of Vanadia Catalysts Supported on Different Carriers by TPD TPR

- Introduction to Chemical Adsorption Analytical Techniques and their Applications to Catalysis

- Microchannel Reactor for Fischer-Tropsch Synthesis- Adaptation of a Commercial Unit (PID-Micromeritics Microactivity Reference)

- PID App Note: Customer Success Story

Adsorbents and Membranes

- Advanced Pore Size Analysis of Microporous and Ultra-microporous Materials

- Breakthrough Adsorption: Theory and Analysis of Adsorption in Zeolites and Metal-organic Frameworks (MOFs)

- Carbons, Zeolites and Molecular Sieves: Material Characteristics and Solutions for Characterization

- Direct Air Capture (DAC) of CO2 and the Important Role of Porous Materials in DAC Technology

- Gas Sorption Characterization of Metal Organic Frameworks (MOFs)

- MOF You Tube Playlist

Catalyst

- Important and powerful techniques used in the characterization of solids

- A Detailed Procedure for a Catalytic Process

- Structured Catalysts and Reactors for the Transformation of CO2 to Useful Chemicals

- A Detailed Procedure for a Catalytic Process

- Chemisorption You Tube Playlist

- Micromeritics AutoChem II 2920 Automated Catalyst Characterization System

- 3Flex: Surface and Catalyst Characterization

- Application notes

-

Adsorbents and Membranes

- Analysis of adsorbents for direct air capture of carbon dioxide using breakthrough analysis

- Using the ASAP 2020 for Determining the Hydrogen Adsorption Capacity of Powders and Porous Materials

- Micropore Analysis of Zeolites Using the ASAP 2420

- Adding a Custom Model to the NLDFT Library: A CO2 GCMC Model for Carbons

- Characterization of Carbons Using a Micromeritics 3Flex

- Adding a custom model to the NLDFT library – a CO2 GCMC model for carbons

- Carbon Dioxide Characterization of Carbons with the TriStar II 3020

- Diffusion of Nitrogen and Methane in Clinoptilolites Tailored for N2-CH4 Separation (ASAP 2010)

- The Heat of Adsorption of Hydrogen Gas on Lanthanum Pentanickel

- Multicomponent Breakthrough Adsorption Water/ethanol Competitive Adsorption On A Zeolite

Catalyst

- Paper: On the Application of an In Situ Catalyst Characterization System (ICCS) and a Mass Spectrometer Detector as Powerful Techniques for the Characterization of Catalysts

- Paper: Confirmation of Pore Formation Mechanisms in Biochars and Activated Carbons by Dual Isotherm Analysis

- Effect of O2 Traces in the Carrier Gas on Quantifying the Active Species in Catalysts

- Evaluating Catalyst Substrates with the GeoPyc

- Temperature-Programmed Reduction Using the AutoChem

- Characterization of Acid Sites Using Temperature-Programmed Desorption

- Characterization of Supported Palladium, Hydrogen Sorption – by Jason Exley

- Characterization of Vanadia Catalysts Supported on Different Carriers by TPD TPR

- Introduction to Chemical Adsorption Analytical Techniques and their Applications to Catalysis

- Microchannel Reactor for Fischer-Tropsch Synthesis- Adaptation of a Commercial Unit (PID-Micromeritics Microactivity Reference)

- PID App Note: Customer Success Story

- Videos

-

Adsorbents and Membranes

- Advanced Pore Size Analysis of Microporous and Ultra-microporous Materials

- Breakthrough Adsorption: Theory and Analysis of Adsorption in Zeolites and Metal-organic Frameworks (MOFs)

- Carbons, Zeolites and Molecular Sieves: Material Characteristics and Solutions for Characterization

- Direct Air Capture (DAC) of CO2 and the Important Role of Porous Materials in DAC Technology

- Gas Sorption Characterization of Metal Organic Frameworks (MOFs)

- MOF You Tube Playlist

Catalyst

- Important and powerful techniques used in the characterization of solids

- A Detailed Procedure for a Catalytic Process

- Structured Catalysts and Reactors for the Transformation of CO2 to Useful Chemicals

- A Detailed Procedure for a Catalytic Process

- Chemisorption You Tube Playlist

- Micromeritics AutoChem II 2920 Automated Catalyst Characterization System

- 3Flex: Surface and Catalyst Characterization

- Links and Brochures

How Can We Help?

Customers choose Micromeritics for our diverse world leading high-performance systems, expert application staff, and factory-trained engineers spanning many industries around the globe. We are here to provide sustainable solutions for Net-Zero Technologies and accelerate both R&D and commercialization with quality data, customer service, our particle testing lab, and virtual or onsite product demonstrations.